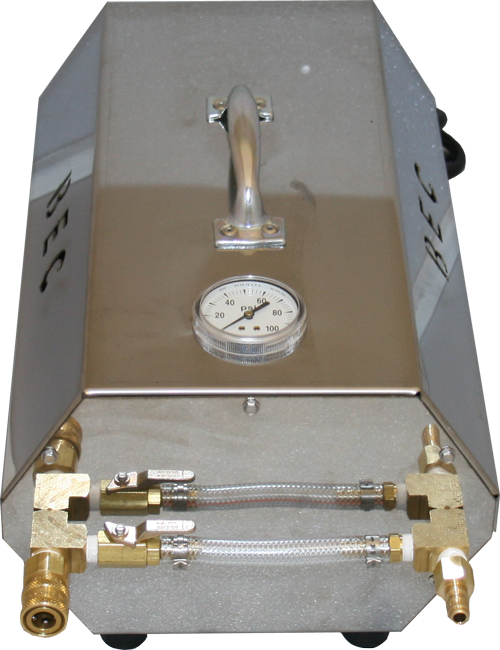

Electric Re-Circulating Draft Beer Line Cleaning Pump – 20’ to 300’ Runs

Brand: Micro Matic

Product Specifications

Additional Information

Fulfillment Options

Description

Ensure clean beer lines with our Re-Circulating Electric Beer Line Cleaning System! Re-circulation cleaning creates a turbulent flow, which is 80 times more effective than merely soaking a beer line with cleaning chemicals. A clean draft beer system results in fresh-tasting beer, more profit for the retailer, and more keg sales!

The Re-Circulating Electric Beer Line Cleaning System is ideal for line runs between 20' to 300' and offers excellent performance and value for the professional beer line cleaner!

FEATURES

- Use: For line runs between 20' to 300'

- Corrosion Resistant: Hard coat finish on pump components to resist cleaning chemical corrosion

- Portable: Cordless design and quick disconnect hoses for easy transport

- User Friendly: Body-mounted On/Off switch allows for easy control

- Consistent Usage: Built-in 15 minute timer

- Temperature Resistant Hose: Hoses (6' length, 3/8" I.D.) remain flexible at low temperatures

- Robust: Stainless steel case for durability

- Power Cord: Not Included. Purchase 5-15P 115v cord separately.

NOTE: Always use proper "brewery-approved" Beer Line Cleaning Chemical when cleaning lines. Use a turbulent circulation action for a minimum of 15 minutes (Brewers Association recommended standard).

RULES FOR SAFE OPERATION

Safety precautions are essential when any electrical or mechanical equipment is involved. These

precautions are necessary when using, storing, and servicing electromechanical equipment.

Using this equipment with the respect and caution demanded will considerably lessen the

possibilities of personal injury. If safety precautions are overlooked or ignored, personal injury or

property damage may occur.

This unit was designed for specific applications. It should not be modified and / or used for any

application other than those for which it was designed. If there are any questions regarding its

application or technical assistance call 1-866-327-4159.

Read this manual carefully - know your equipment. Consider the application, limitations and the

potential hazards specific to your unit.

1. Only use a three wire extension cord, with grounded prong. Use a portable plug GFCI

device, a 3-prong power cord with a GFCI device or a GFCI equipped outlet to protect

from ground fault shock.

2. Do not touch pug or outlet with wet hands.

3. Avoid accidental starts. Turn switch “off” before connecting or disconnecting cord at

electrical outlets.

4. Water spray must never be directed toward any electrical wiring or directly toward the

machine itself or fatal electric shock may occur.

5. Never carry unit by the cord or hoses. Do not pull on cord to disconnect from outlet.

6. To prevent damage, the cord should not be crushed, placed next to sharp objects or

near heat.

7. Check power cords before using. Damaged cords can reduce performance or cause a

fatal electric shock.

8. Never allow children to operate this equipment.

9. Wear safety glasses and/ or goggles while operating.

10. Disconnect power plug form the outlet when not in use and prior to the detaching of

the cleaning hose.

11. Prior to starting in cold weather, be sure ice has not formed in any part of the

equipment.

12. To allow free air circulation, the unit should not be covered during operation.

OPERATING PROCEDURE

1. Place siphon tube in pail of water or premixed cleaner.

CAUTION: Make certain the end strainer is in place, clean, and the tube is not clogged or

kinked. Failure to do so could allow dirt, grit, sand, etc. to be sucked into the unit. This

could block valves and cause the unit to malfunction. If filters are not in place, the warranty

is void. Water temperature above 140°F should be avoided

2. Connect the threaded adapter on the discharge line to the draft system in your normal

manner.

3. Make certain the red handle flow valve on the front of the machine is in the open position

(parallel to the hose). If this valve is closed, the pump will not prime.

4. The pump has an internal control that causes the pump to automatically bypass ( re-circulate

the liquid) if restrictions in the system cause pressure to rise above 60 PSI. Use the red

handled ball valve to further control discharge flow. The more you close the valve, the less

liquid will flow into the lines, while lowering the pressure in the system.

CAUTION

Line pressure above 50 PSI can damage the lines and cause failure of couplers in the system.

PROTECTING YOUR MACHINE AGAINST DAMAGE

1. DON’T run your unit without inlet water hose in place. This will damage the pump and VOIDS

THE WARRANTY.

2. DON’T let particulate matter get into the pump. Foreign material can ruin the pump

immediately. THIS VOIDS THE WARRANTY. To keep particles out, never operate your unit

without the filter properly installed on the suction tube, and clean. See maintenance procedure

below for further details.

3. Always store your machine in a location where the temperatures will not fall below 32° F. The

pump in this machine is susceptible to damage if frozen.

FREEZE DAMAGE IS NOT COVERED BY WARRANTY!

FROZEN PUMPS

You are cautioned not to allow the pump to freeze. There is only a very small amount of water in

the pump - it freezes quickly!!!

In cold weather, it is suggested the pump be transported inside your vehicle - not in the trunk or

bed of a truck.

If the pump does freeze, it must be replaced. You may purchase replacement pumps through the

Customer Service department.